In the realm of modern construction, technology has emerged as a powerful driver, revolutionizing the way projects are designed, executed, and managed. From groundbreaking innovations to sophisticated tools, technology has transformed the construction industry, enhancing efficiency, safety, and sustainability. Explore the pivotal role of these advancements have made in contemporary construction and its impact on the industry as a whole.

Design and Planning

In the past, designing and planning a construction project involved intricate blueprints, manual calculations, and significant amounts of time. However, technology has streamlined these processes, making them more accurate, efficient, and collaborative. Building Information Modeling (BIM) software has gained immense popularity, enabling architects, engineers, and contractors to create detailed 3D models, identify potential clashes, and simulate real-world scenarios before construction even begins. This tool facilitates better decision-making, reduces errors, and optimizes resource allocation, ultimately resulting in improved project outcomes.

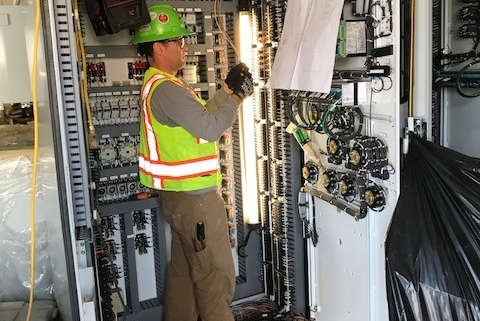

Construction Techniques and Equipment

Technology has introduced a wide array of innovative construction techniques and equipment, transforming the way buildings are erected. Advanced machinery and robotics have increased productivity, reduced labor costs, and enhanced safety on construction sites. Drones are employed for aerial surveys, inspections, and monitoring progress, providing valuable data and imagery. Modular construction, utilizing prefabricated components manufactured off-site, has gained popularity due to its time and cost efficiency. 3D printing is another game-changer, allowing for the creation of complex architectural elements with unprecedented speed and precision.

Technology within Sustainable Construction

With growing environmental concerns, technology has played a crucial role in promoting sustainable construction practices. Energy-efficient building materials, such as green concrete and recycled steel, are now being used to minimize carbon footprints. Smart buildings equipped with advanced sensors and automation systems optimize energy consumption, improve indoor air quality, and reduce waste. Furthermore, renewable energy sources, like solar panels and wind turbines, are integrated into construction projects to generate clean energy on-site. These technological advancements align construction with sustainable development goals, creating environmentally friendly and future-proof structures.

Project Management and Communication

Efficient project management and streamlined communication are vital for successful construction endeavors. Technology has revolutionized these aspects by introducing cloud-based project management systems that centralize data, streamline workflows, and enhance collaboration. Real-time updates, document sharing, and mobile applications enable stakeholders to access critical project information anytime, anywhere. Additionally, virtual and augmented reality technologies are employed to visualize construction projects, facilitating better communication and decision-making among team members.

Safety and Risk Mitigation

Construction sites are inherently hazardous environments, but technology has significantly improved safety measures and risk mitigation. Wearable devices, such as smart helmets and vests, equipped with sensors and GPS trackers, monitor workers’ vital signs, detect potential hazards, and ensure adherence to safety protocols. IoT (Internet of Things) devices and cloud-based platforms enable real-time monitoring of construction sites, identifying risks and allowing for timely intervention. Artificial intelligence and machine learning algorithms analyze data patterns to predict potential accidents, enhancing proactive safety measures.

Technology in Construction

Every aspect of modern construction has evolved, from project delivery, and design to completion. Technology has introduced efficiency, accuracy, and sustainability while mitigating risks and enhancing safety. As the industry embraces advancements like BIM, drones, 3D printing, and IoT, the construction process becomes more streamlined, cost-effective, and environmentally friendly. With ongoing research and development, technology will continue to shape the future of construction, enabling the creation of smarter, more sustainable, and innovative structures.

Visit The Builders Association to learn more about technologies impact on modern construction